Effera API

Overall, Efferas APIs provide the opportunity to optimize plant operations, enhance efficiency, strengthen decision-making processes, and support various industry needs through access to comprehensive telemetric data.

What is an API?

An API (Application Programming Interface) is a set of rules and protocols that allow software applications to communicate with each other. Effera offers several APIs for third-party integrations. These APIs make different functions possible. This includes handling telemetry data, basic operations on projects and construction sites, retrieving information about machines, recording arrival and departure times for people on the construction site, as well as access to historical location and time series data for machines. The APIs provide valuable insights and opportunities for integration with external systems, and users can try the APIs through our developer portal.

Our products

A product consists of one or more APIs.

Product

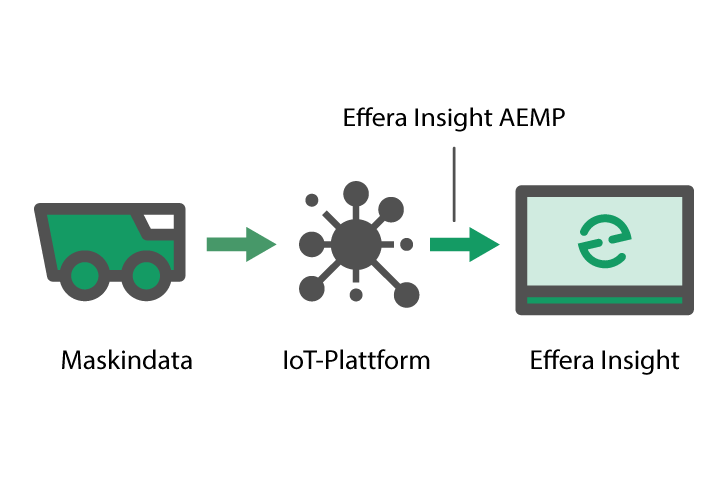

Effera Insight AEMP

AEMP is an ISO standard (ISO 15143-3) that enables the exchange of telemetry data. It provides standardized communication from various types of construction equipment and machines, such as excavators, wheel loaders and dump trucks.

The Effera Insight AEMP API interprets known/standardized signals and makes them understandable to us, allowing us to benefit from the telemetry data, across the entire fleet regardless of manufacturer in our technology platform, Effera Insight.

Who can it be used by?

Third-party integrations and contractors with knowledge of the AEMP standard.

What value does this have for me?

A snapshot of the entire fleet's last known/standardized signals.

APIs in product

Effera Insight AEMP

GET Fleet and Token: The token is used to authenticate the user, while GET Fleet is used to retrieve the fleet information using the received token. GET Fleet and Token are part of the AEMP standard and are therefore required.

Product

Effera Core

Our CRUD API. CRUD stands for Create, Read, Update and Delete and refers to basic operations that can be performed on data in a system. The CRUD API is an interface that allows these four fundamental operations on resources (data entities) through the Effera Insight platform.

Who can it be used by?

Third-party integrations and for contractors who want to extract information, manage and report on projects, construction sites and users.

What value does this have for me?

Integrate with other systems, so you can transfer data between external systems and Effera Insight, and vice versa.

APIs in product

Effera Insight Core

Third-party integrations and for contractors who want to extract information, manage and report on projects, construction sites and users.

Product

Effera Insight Machine

Our Machine API provides the ability to retrieve information about machines from Effera Insight's machine register. You can search for a specific machine using various identifiers, get information about all machines or find machines based on manufacturer.

Who can it be used by?

Third-party integrations, contractors, and other APIs such as IoT Location and IoT Telemetry.

What value does this have for me?

Get an overview of machines with ID, VIN, serial number, manufacturer, model, etc.

APIs in product

Effera Insight Machine

Search for a specific machine, retrieve multiple machines or find machines based on manufacturer.

Product

Effera Insight Workforce

Our dedicated crew list API records the arrival and departure times of people on site, providing a snapshot of who is on the site right now. The API also provides the ability to generate comprehensive historical reports containing aggregate crew arrival and departure times for selected construction sites.

Who can it be used by?

Third-party integrations and HSE.

What value does this have for me?

See who is on site right now, pull up instant reports and generate historical reports.

APIs in product

Effera Insight Workforce

Get historical reports per plant as well as instant reports for individuals and plant sites.

Product

Effera IoT Location

Specific API for historical location of an individual machine. It is possible to extract data over a certain period of time and export it in GPX format.

Who can it be used by?

Systems for fleet management, project managers and planners, the service and maintenance industry, contractors, the rental industry and third-party integrations.

What value does this have for me?

Makes it possible to follow machines and record their movements, routes and positions on the construction site over time. The practical applications of this are countless.

APIs in product

Effera IoT Location

Get location over time based on various parameters such as manufacturer, serial number and ID.

Product

Effera IoT Telemetry

Historical time series data for a machine, where we present all signals or events we can interpret from available sources in a standardized way, for example in JSON or CSV format.

Who can it be used by?

Project managers and planners, the service and maintenance industry, contractors, operations managers and third-party integrations.

What value does this have for me?

The utility of this data access is extensive and forms the basis for further calculations in various areas. This includes efficiency, environment, manufacturer information, maintenance, consumption and more. This data resource provides valuable insight that can support analyzes and decisions across various aspects of facility operations.

APIs in product

Effera IoT Timeseries Telemetry

Get telemetry data for equipment and machines within a specified time period based on various parameters such as ID, manufacturer, serial number and ID. The API also provides the ability to retrieve telemetry data for an entire project.

Effera IoT Event

Get an overview of events that have been registered on the machine in a selected time period. This can be for maintenance carried out, arrival or departure from facilities, as well as information about who has operated the machine. Events can be generated based on various identifiers such as manufacturer, serial number or ID.

Effera IoT Telemetry

Get telemetry data from a specific machine device, such as eAccess MachineController or eAccess EquipmentTracker. Identified by device ID.